How to Choose the Right Pharmaceutical Supplier for Your Business Needs

In the ever-evolving landscape of the pharmaceutical industry, selecting the right pharmaceutical supplier is crucial for businesses aiming to maintain high standards of quality and efficiency. Experts in the field emphasize the importance of making a well-informed decision. Dr. Sarah Thompson, a renowned pharmaceutical supply chain consultant, states, “The choice of a pharmaceutical supplier can significantly impact not only the quality of products but also the overall success of your business.”

With numerous factors to consider, such as reliability, regulatory compliance, and cost-effectiveness, businesses must navigate this complex environment thoughtfully. Ensuring that the chosen pharmaceutical supplier aligns with the specific needs and goals of the company is essential for optimizing operations and achieving sustainable growth. As competition intensifies, understanding these dynamics becomes even more critical for those looking to thrive in the pharmaceutical sector.

By exploring key characteristics and strategies for evaluating pharmaceutical suppliers, organizations can make decisions that fortify their market positioning and enhance their product delivery capabilities, thereby better serving their clientele and fostering long-term success.

Identifying Your Business Requirements for Pharmaceutical Supplies

When selecting a pharmaceutical supplier, the first step is to clearly identify your business requirements. This involves evaluating the scope of your operations, the types of pharmaceutical products you need, and the volume of supplies required. Consider the specific formulations or classifications of medications relevant to your business—whether you're focusing on over-the-counter products, prescription medications, or specialized compounds. Understanding these elements will help you narrow down potential suppliers who can meet those specific needs.

Additionally, it’s essential to consider regulatory compliance and quality assurance in your requirements. Identify any certifications or standards necessary for your operation, such as Good Manufacturing Practice (GMP) or Good Distribution Practice (GDP). Ensure that the suppliers you are considering have a proven track record of compliance with industry regulations and quality control. By prioritizing these requirements, you can align your selection process with suppliers who not only meet your product needs but also adhere to the safety and regulatory standards essential for maintaining trust and reliability in the pharmaceutical sector.

Pharmaceutical Supplier Evaluation Criteria

Evaluating Supplier Credentials and Certifications

When selecting a pharmaceutical supplier, evaluating their credentials and certifications is paramount. Start by verifying if the supplier adheres to regulatory standards set by relevant health authorities. This includes checking for certifications such as Good Manufacturing Practice (GMP) and Good Distribution Practice (GDP). These certifications indicate that the supplier maintains high-quality controls and processes that comply with industry regulations, ensuring that the products you receive are safe and effective for your business needs.

Additionally, consider the supplier’s history of compliance and any previous audits they have undergone. An established track record of maintaining regulatory standards can reflect their commitment to quality and reliability. Requesting documentation of their certifications and any recent inspection reports can provide insight into their operational integrity. Furthermore, networking with other industry professionals can offer valuable feedback on the supplier's reputation, helping you make a more informed decision about your pharmaceutical partnerships.

Assessing Quality Control and Compliance Standards

When selecting a pharmaceutical supplier, one of the most critical aspects to consider is the supplier's quality control and compliance standards. According to a 2021 report by the International Pharmaceutical Federation, over 40% of pharmaceutical recalls are tied to quality issues, underscoring the importance of partnering with a supplier that adheres to stringent quality management systems. Effective quality control measures, such as Good Manufacturing Practices (GMP), ensure that products are consistently produced and controlled to the quality standards appropriate to their intended use.

Furthermore, compliance with regulatory requirements is essential for maintaining product safety and efficacy. The U.S. Food and Drug Administration (FDA) mandates that pharmaceutical suppliers comply with rigorous standards, which are outlined in their Quality System Regulation. A supplier that demonstrates robust compliance frameworks not only reduces the risk of costly recalls but also maintains the integrity of your supply chain. Reports from the European Medicines Agency illustrate that suppliers with established quality assurance protocols are 60% less likely to face compliance-related issues. Hence, assessing a supplier's quality control procedures and their commitment to compliance is paramount for any business looking to establish a reliable and safe pharmaceutical supply chain.

Comparing Pricing and Payment Options

When evaluating pharmaceutical suppliers, one of the critical factors to consider is pricing and payment options. A recent report from the Global Pharmaceutical Supply Chain Insights indicates that around 40% of businesses overspend due to a lack of transparency in supplier pricing. This highlights the importance of comparing quotes from multiple suppliers to ensure competitive rates. Companies should aim to obtain detailed pricing structures that include not only the base costs but also any additional fees for shipping, handling, or potential discounts for bulk purchases.

In addition to straightforward pricing, flexible payment options can significantly affect cash flow management. According to a survey by the Pharmaceutical Sales Council, organizations that partnered with suppliers offering diverse payment terms saw a 30% improvement in their liquidity over the past year. It's advisable to look for suppliers who can accommodate various payment methods, such as net payment terms, installment plans, or electronic invoicing, to align better with your financial strategy. By analyzing both pricing and payment options, businesses can make informed decisions that streamline operations and maximize profitability.

How to Choose the Right Pharmaceutical Supplier for Your Business Needs - Comparing Pricing and Payment Options

| Supplier Type | Pricing Model | Payment Terms | Minimum Order Quantity | Lead Time |

|---|---|---|---|---|

| Wholesaler | Bulk Pricing | Net 30 Days | 100 Units | 2 Weeks |

| Distributor | Tiered Pricing | Net 15 Days | 50 Units | 1 Week |

| Manufacturer | Cost-Plus Pricing | Prepaid | 200 Units | 4 Weeks |

| Online Supplier | Flat Rate | Immediate Payment | No Minimum | 3 Days |

| Local Supplier | Negotiable Pricing | Net 30 Days | 50 Units | 1-2 Weeks |

Establishing Communication and Support Channels with Suppliers

Establishing effective communication and support channels with your pharmaceutical supplier is crucial for the success of your business. First and foremost, it is essential to identify the key players within the supplier’s organization who will be your main points of contact. This typically includes sales representatives, customer service agents, and technical support staff. Building a strong relationship with these individuals can foster open lines of communication, allowing for quick resolution of issues that may arise during the supply process. Regular check-ins and meetings can help to ensure that both parties are aligned on expectations, timelines, and any potential challenges.

In addition to identifying key contacts, implementing a structured communication plan can enhance the collaboration with your supplier. Utilizing various methods, such as email updates, phone calls, and online platforms for real-time communication, can facilitate better information exchange. Moreover, establishing a feedback loop where both parties can share insights and concerns helps to build trust and enables continuous improvement in the partnership. By prioritizing communication and support, businesses can ensure that their pharmaceutical supply chain operates smoothly and efficiently, ultimately contributing to their overall success.

Related Posts

-

What is the Role of a Pharmaceutical Supplier in Global Supply Chains

-

How to Source High Quality Pharmaceutical Chemicals for Global Supply Chains

-

Mastering Pharma Material Procurement: A Comprehensive Guide for Global Buyers

-

Raw Pharmaceutical Excellence Crafted in China for a Global Tomorrow

-

Navigating the Landscape of Best Pharmaceutical Supplier Choices for Your Business

-

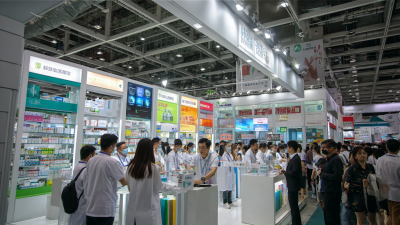

Exploring Pharmaceutical Supply Trends at the 138th Canton Fair in China 2025