2026 Best Peptide Api Manufacturing Techniques Explained?

The world of Peptide API manufacturing is evolving rapidly. As researchers seek new methods to create effective therapies, the demand for reliable peptide production grows. This article explores the best manufacturing techniques for peptides, focusing on innovations expected to shape the industry by 2026.

Peptide APIs play a crucial role in drug development. However, the complexities in their synthesis present numerous challenges. From scalability to purity, each step requires precision. Techniques vary greatly, and some methods may not meet rising industry standards. The quest for efficient processes often leads to trial and error, highlighting the need for continuous improvement.

As we delve into the best peptide API manufacturing techniques, it’s essential to consider both advancements and shortcomings. While some techniques show promise, they also raise questions regarding consistency and efficiency. This exploration will shed light on how manufacturers can adapt to the evolving landscape and address existing challenges in peptide production.

Overview of Peptide APIs and Their Importance in Pharmaceuticals

Peptide active pharmaceutical ingredients (APIs) play a crucial role in the pharmaceutical industry. They are essential for developing various therapeutic agents, particularly for chronic diseases like diabetes and cancer. According to industry reports, the global peptide therapeutics market is projected to reach $62 billion by 2026. This growth reflects the increasing demand for innovative treatments.

Peptides offer several advantages over traditional drugs. They often have a higher specificity for their targets. This specificity can result in fewer side effects. Additionally, peptides are generally more stable in the body compared to small-molecule drugs. However, producing these compounds can be challenging. Synthesis techniques must ensure high purity and yield. Many manufacturers still face issues related to scalability and cost-effectiveness.

Recent advancements have improved peptide synthesis methods. Technologies like solid-phase peptide synthesis (SPPS) have gained traction. These methods can enhance efficiency and reduce production times. Yet, quality control remains a critical concern. Ensuring consistency in peptide production is vital. Inconsistent product quality can undermine therapeutic efficacy. This highlights the need for continuous improvement in manufacturing techniques.

Key Manufacturing Techniques for Peptide API Production

Peptide API production requires specialized techniques to ensure quality and efficacy. Solid-phase synthesis is one prominent method. This technique allows for the efficient assembly of peptides. In this process, amino acids are attached to a solid support. This method simplifies purification steps and reduces the risk of contamination. However, the challenge lies in the removal of protecting groups during synthesis, which can sometimes lead to incomplete reactions.

Another technique is liquid-phase synthesis, commonly used for longer peptides. This approach offers better control over the reaction conditions. It allows for more complex peptide structures. Nonetheless, it can become cumbersome and may result in lower yields, requiring careful optimization. Attention to detail is crucial here. Experimentation with various solvents and temperatures can lead to significant improvements. The quest for efficiency often comes with setbacks. Therefore, manufacturers must balance innovation with reliability.

Understanding Solid-Phase vs. Solution-Phase Peptide Synthesis

Peptide synthesis is vital in many fields, from pharmaceuticals to research. Two main techniques are solid-phase synthesis and solution-phase synthesis. Each method has its own advantages and limitations.

In solid-phase synthesis, the peptide grows on a solid support. This allows for easy purification after each step. However, controlling the reaction conditions can be tricky. You might encounter issues like incomplete coupling or side reactions. Achieving high yield can sometimes feel like a gamble.

Solution-phase synthesis is another approach. In this method, peptides are synthesized in a liquid state. It's often simpler to manage. However, purification can be challenging. The presence of many side products can complicate the process. It's important to weigh the pros and cons of each method carefully.

**Tip:** Consider your desired peptide length and complexity. These factors can significantly influence your choice of technique.

Remember that optimization is key in peptide synthesis. Small adjustments in reagents or conditions can lead to better outcomes. Don’t hesitate to experiment and refine your processes.

**Tip:** Keep thorough records of all your synthesis runs. This will help you identify patterns and improve your techniques over time.

2026 Best Peptide API Manufacturing Techniques: Solid-Phase vs. Solution-Phase Peptide Synthesis

Quality Control Measures in Peptide API Manufacturing

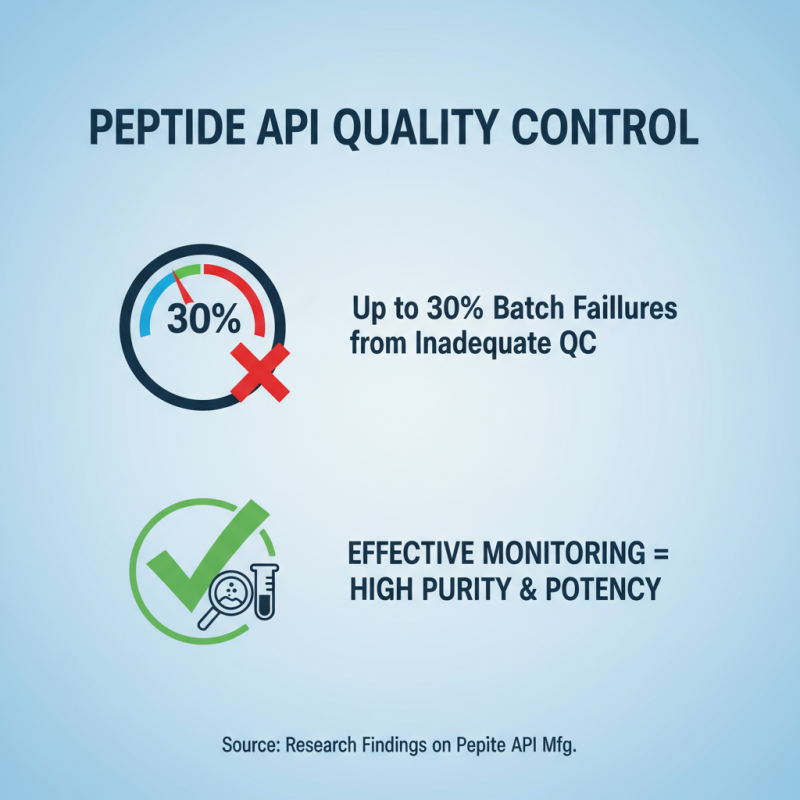

Quality control in peptide API manufacturing is crucial. Research indicates that up to 30% of batch failures occur due to inadequate quality control measures. Effective monitoring ensures high purity and potency of the final product.

One key aspect involves analytical testing. Techniques like HPLC and mass spectrometry are typically used to detect impurities. However, not all manufacturers implement these methods consistently. This inconsistency can lead to significant quality variations. Data from recent studies indicate that 10-15% of low-quality peptide APIs may enter the market undetected.

Another essential measure is process validation. This includes establishing operating parameters that consistently produce a product of predetermined quality. Yet, many companies lack rigorous validation processes, leading to questions about their reliability. Reports suggest that around 20% of manufacturers do not meet these essential validation standards, raising concerns over long-term safety and efficacy.

Innovations in Peptide API Production Technologies

The landscape of peptide API production is rapidly evolving. Innovations are surfacing, pushing the boundaries of what is possible in this field. Advanced synthesis techniques are enhancing yields and purity. New automation technologies are also improving efficiency, reducing human error. These developments are essential as demand for peptide-based therapies increases.

Additionally, improved purification methods are making a significant impact. Techniques such as high-performance liquid chromatography (HPLC) are now more accessible. This change is reducing costs while maintaining quality. However, challenges remain. Not all facilities can implement these innovations smoothly. Some lack training or resources, which can lead to inconsistencies.

Moreover, scaling production effectively is complex. There are concerns about maintaining quality during larger batch productions. Each innovation brings new questions. Can the new methods adapt to diverse peptide sequences? Will they ensure the same level of efficacy? As the industry advances, continuous reflection on these questions is crucial for future success.

2026 Best Peptide Api Manufacturing Techniques Explained

| Technique | Description | Advantages | Current Trends |

|---|---|---|---|

| Solid-phase peptide synthesis (SPPS) | A method that involves the sequential addition of protected amino acids to a solid resin. | High purity, rapid synthesis, and ease of automation. | Increased automation and integration of AI for monitoring. |

| Liquid-phase peptide synthesis (LPPS) | A traditional method performed in solution, allowing for complex peptide synthesis. | Flexibility in synthesis and modification during the process. | Increased focus on yield optimization and reducing solvent use. |

| Recombinant DNA technology | Involves using genetic engineering to produce peptides through microbial fermentation. | Scalability and cost-effectiveness for large-scale production. | Advancements in genetic editing for enhanced production strains. |

| Parallel synthesis | Simultaneous synthesis of multiple peptides using a microarray or similar technology. | High-throughput capabilities for rapid development. | Integration with analytical tools for real-time data collection. |

Related Posts

-

How to Effectively Scale Peptide API Manufacturing for Optimal Yield and Purity

-

Maximizing ROI: The After-Sales Service Edge in Best Peptide API Manufacturing

-

Ultimate Guide to Sourcing the Best Peptide Api Manufacturing for Your Business Needs

-

10 Best Practices for Peptide API Manufacturing to Maximize Efficiency

-

Exploring Peptide Api Manufacturing Opportunities at 2025 China 138th Canton Fair with Market Growth Insights

-

Revolutionizing Peptide API Manufacturing: Innovations for the Future of Biopharmaceuticals