2026 Best High Quality Raw Materials for Sustainable Development?

In today's rapidly evolving economy, the demand for High Quality Raw Materials has never been greater. As sustainability becomes a key focus, industries are pressured to refine their sourcing strategies. According to a recent report by the World Economic Forum, over 70% of global manufacturers are now prioritizing sustainable materials. This shift reflects a growing recognition of environmental impact and resource scarcity.

Experts emphasize the need for high-quality options. Dr. Elena Richards, a renowned materials scientist, states, "Investing in High Quality Raw Materials is not just an ethical choice; it’s essential for future resilience." Her insights highlight the dual necessity of quality and sustainability. However, challenges remain. The market can be unpredictable, with quality assurance often overlooked in favor of cost-cutting.

While many companies aim to adopt sustainable practices, discrepancies still exist. Not all materials marketed as "sustainable" meet the required standards. Reports indicate that nearly 40% of labeled sustainable materials fail to meet rigorous certification benchmarks. This raises critical questions about transparency and accountability in the supply chain. The journey toward fully sustainable practices in sourcing high-quality materials is complex, yet vital for a truly sustainable future.

Overview of Sustainable Development and Raw Material Importance

Sustainable development relies heavily on the careful selection of raw materials. These materials must be renewable, non-toxic, and sourced responsibly. From bio-based plastics to recycled metals, each choice impacts the environment significantly. For instance, the production of fiber from recycled textiles reduces waste and lowers resource consumption.

Many industries still rely on outdated practices. They overlook the importance of utilizing sustainable materials in their production processes. Some businesses may prioritize cost over eco-friendliness. This leads to increased pollution and resource depletion. It is essential for manufacturers to reflect on their material sources.

The challenge lies in balancing quality with sustainability. Some high-quality materials are hard to source sustainably. Innovations in material science can address this issue. Exploring alternatives like agricultural waste could provide viable solutions. The journey toward sustainable development is indeed complex, yet it is necessary for our planet's future.

2026 Best High Quality Raw Materials for Sustainable Development

| Raw Material | Source | Sustainability Rating | Applications | Carbon Footprint (kg CO2e/kg) |

|---|---|---|---|---|

| Recycled Aluminum | Post-consumer scrap | A+ | Construction, Packaging | 0.5 |

| Bamboo | Sustainable forests | A | Furniture, Flooring | 0.2 |

| Hemp | Organic farms | A | Textiles, Biocomposites | 0.4 |

| Recycled Plastic | Post-consumer products | B | Packaging, Construction | 1.0 |

| Cork | Cork oak forests | A+ | Flooring, Insulation | 0.1 |

Key Characteristics of High-Quality Raw Materials for Sustainability

In the quest for sustainable development, high-quality raw materials play a crucial role. They offer durability, efficiency, and reduced environmental impact. According to a report from the World Resources Institute, sustainably sourced materials can reduce greenhouse gas emissions by up to 30%. This shift is not just beneficial for the planet; it also enhances product lifecycle.

Key characteristics of these materials include renewability and recyclability. For instance, materials like bamboo or hemp grow quickly and require less water. The Ellen MacArthur Foundation emphasizes that utilizing such materials can significantly lower waste, pushing the circular economy forward. However, challenges exist. Many high-quality materials still rely on complex supply chains that can compromise sustainability.

Additionally, economic viability remains a concern. Lower-cost alternatives often tempt businesses, despite their environmental costs. According to research from the International Institute for Sustainable Development, the long-term savings from using high-quality materials can outweigh initial investments. Still, many companies hesitate to make this switch. Balancing cost with sustainability is a perennial challenge. It's vital to continually reassess sourcing strategies for raw materials to align with sustainability goals.

Prominent Materials Supporting Renewable Energy and Green Technology

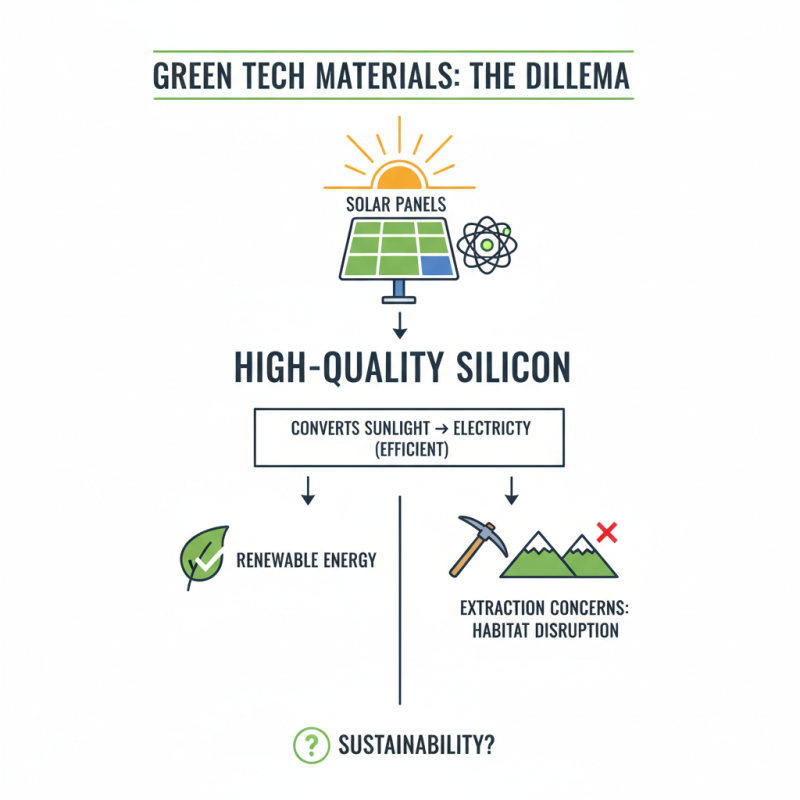

Prominent materials play a crucial role in renewable energy and green technology. For instance, solar panels require high-quality silicon. This material converts sunlight into electricity efficiently. However, the extraction process can be environmentally taxing. Mining silicon can lead to habitat disruption, raising concerns about sustainability.

Another key material is lithium, essential for batteries in electric vehicles. Lithium-ion batteries boost energy storage but rely heavily on mining. The environmental impact of lithium extraction is significant. Water consumption and pollution from mining operations must be addressed.

Recycling these materials presents a solution. Recovering silicon and lithium reduces waste and lowers the demand for new mining. Innovations in recycling technology could enhance the circular economy. However, the scalability of recycling methods is still in question. Developing efficient systems involves overcoming many challenges. Exploring alternative materials is also necessary for future sustainability.

Innovative Sources of Eco-Friendly Raw Materials in Construction

The construction industry is evolving. The focus has shifted towards

eco-friendly raw materials. A report from the

Global Sustainability Forum revealed that over 50% of construction materials

could potentially be derived from recycled sources by 2026. This change helps

reduce waste and minimize environmental impact.

Innovative sources of materials are emerging. For instance, manufacturers are exploring

bamboo and reclaimed wood as

alternatives to traditional timber. Bamboo grows rapidly and can thrive in various climates,

making it an attractive option. Reclaimed wood brings character to buildings while conserving

natural resources. It is estimated that increasing the use of reclaimed materials could

reduce carbon emissions by 30% in the sector.

However, challenges remain. The quality of recycled materials

can be inconsistent. Many builders worry about durability and safety. Without

rigorous standards, some eco-friendly materials may not perform as expected. Continuous

research and development are crucial. Testing different blends and compositions will pave

the way for reliable, eco-friendly construction materials.

Challenges and Solutions in Sourcing Sustainable Raw Materials

Sourcing sustainable raw materials is crucial for a greener future. However, challenges remain. The demand for eco-friendly materials continues to rise, yet the supply chain is often inefficient. According to the Global Sustainability Report 2023, only 30% of raw materials are sustainably sourced. This gap signals a need for change.

Logistical issues frequently hinder the transition to sustainable materials. Transportation costs can be high. Moreover, many regions lack the technology for efficient sourcing. A study by EcoSupply Chain Analytics highlights that nearly 40% of companies struggle with sourcing sustainable alternatives due to these barriers. Overcoming these challenges requires innovative solutions, such as digital technologies that track materials from source to end-use.

Investing in local sourcing can also help mitigate these challenges. It not only reduces transportation emissions but also supports local economies. However, the initial costs may deter companies. Many businesses often hesitate to switch due to perceived risks. The balance between sustainability and profitability remains delicate. Open dialogue within the industry can reveal best practices to help overcome these challenges effectively.

2026 Best High Quality Raw Materials for Sustainable Development

This chart illustrates the projected usage percentages of various sustainable raw materials in 2026. The focus is on increasing reliance on materials that promote sustainability across industries.

Related Posts

-

Trustworthy Quality of Chinese Manufacturing for Global High Grade Raw Materials

-

Strategies for Sourcing Premium Raw Materials Globally

-

How to Source High Quality Raw Materials for Global Market Success

-

The Ultimate Guide to Sourcing High Quality Raw Materials for Your Business Success

-

5 Expert Tips to Source High-Quality Pharmaceutical Raw Materials in 2023

-

Top 10 Peptide Material Manufacturers from China at the 137th Canton Fair